Call Us: 1.800.275.3453

Request a QuoteCall Us: 1.800.275.3453

Request a QuoteComparing Concrete Pads Against Modular Containments

For centuries, humans have built roads, highways, bridges and entire cities out of concrete. When taking this intoconsideration, it may seem natural and logical to use concrete for industrial applications, such as SPCC secondary spill containment. Concrete containment pads have been in use for a long time, but that doesn’t mean their design is full-proof. Modular spill containment (a more recent form of secondary spill containment) may be far more beneficial to meet Environmental Protection Agency (EPA) or Occupational Safety and Health Administration (OSHA) regulations.

This article will briefly discuss the limitations of using concrete containment pads as a secondary containment system and offer a better solution.

Concrete containment pads, structures and systems have long been the traditional solution for adequate secondary containment for various industries. Generally speaking, concrete containment pads consist of a poured concrete foundation, combined with vertical concrete walls, enforced with rebar. Once the concrete is poured, the interior is typically coated with epoxies, tars and polyurethane to prevent spilled chemicals from eating away at the structure.

So, what’s the problem with concrete containment pad design? While it may seem like a perfect solution, concrete secondary containment systems come with some serious limitations and weaknesses. Common limitations of concrete containment pad design include the following:

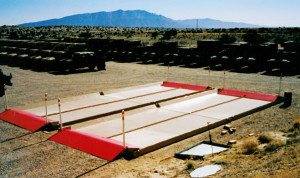

Let’s look at a real-world example of how concrete containment pad design can be flawed. To the left is a concrete secondary containment system built in early 2000. This concrete containment pad was constructed to the highest standards and with the latest technology.

This 80-foot-long, 14-foot-wide concrete containment system cost well over $80,000, with a major site disruption of six weeks from start to finish.

This 80-foot-long, 14-foot-wide concrete containment system cost well over $80,000, with a major site disruption of six weeks from start to finish.

Let’s take a closer look.

Functionally, this concrete containment pad is entirely ineffective for SPCC purposes, as the concrete has cracked in multiple locations.

This secondary containment system has developed cracks that run the entire width of each section, rendering it completely useless. That’s six 14-foot-long cracks!

A better, truly effective solution is a pre-fabricated Polystar Containment Pad that can be installed in just hours. It can be relocated as needed.

These surface-mounted secondary containment systems won’t crack & offer years of performance in the most extreme hot or cold conditions. Modular in all sizes, our secondary spill containment systems work for a variety of applications.

If concrete containment pads are ineffective, what else can facilities use as secondary containment? A better, more effective solution comes in the form of a Containment Pad from Polystar Containment. Our Containment pads are manufactured from fiberglass encapsulated steel and can be customized to meet your specific containment needs and dimensions. Smaller designs can be delivered in a single piece, and larger designs can be manufactured in panels and assembled onsite.

Modular spill containment creates a barrier inside the walls to contain liquids and prevent fuel and other hazardous chemical spills from contaminating the environment. Because the pieces are modular, you can easily reconfigure the size depending on the needed application.

You can install modular spill containment in just five hours and relocate it as necessary. These surface-mounted secondary containment systems won’t crack and offer years of performance in extreme hot or cold conditions.

Polystar Containment can deliver and install (in the lower 48 states) a comparable 80-foot modular spill containment pad system for approximately 60% of the cost of the failed concrete containment pad system above.

In this picture, you can see Polystar Containment’s heavy-duty, drive-on Containment Pad™ for secondary spill containment in action.

Take a look at Polystar Containment’s modular, heavy-duty drive-on containment system – the Camel Tri-Star® for industrial spill prevention in use at a military base.

Are you ready to bring your SPCC compliance into the 21st century? At Polystar Containment, we offer affordable modular spill containment solutions designed for complete reliability. Our selection of industrial and military spill containment solutions won’t crack, leak, decay or crumble over time. More importantly, unlike concrete containment pads, our products can be moved as needed for years of reliable secondary spill containmenteverywhere you go. Contact Polystar Containment today for truly effective spill containment.

Learn more about secondary spill containment with the additional resources below. Polystar Containment is an industry-leading long-term and temporary spill containment equipment provider. With our spill containment products and solutions, you can enhance your preparedness and response capabilities, minimizing the environmental risks associated with hazardous materials handling.